A rare behind-the-scenes look at Canon's Tokyo headquarters and Utsunomiya lens factory reveals the extraordinary human effort behind every camera and lens. During an exclusive visit to one of the world's most celebrated camera companies, the most striking discovery wasn't the advanced technology, but the thousands of passionate individuals whose years of dedication make modern photography possible.

Every Canon camera and lens represents the collective work of countless people across numerous specialized teams. Each function, whether major or minor, and every component requires dozens to hundreds of professionals working five days a week for months or even years. Some innovations take over a decade of behind-the-scenes development before implementation, while many promising ideas never reach production at all.

Canon's imaging department houses an abundance of photography enthusiasts who bring deep passion to their work. Go Tokura, Canon's Executive Vice President, Head of Imaging Group, and Chief Executive of Imaging Business Operations, exemplifies this dedication. Starting as a product designer, one of his earliest and most impactful projects was the Canon T90 in 1986, which would influence the design of every subsequent Canon EOS camera.

Tokura's love for photography has informed his contributions throughout his career, from his early days to his current leadership role. Like nearly every Canon employee encountered at both headquarters and the factory, he continues taking pictures. Canon runs internal photography competitions for employees, creating impressively stiff competition among staff members.

A consistent understanding permeates Canon that photography itself matters profoundly. While the company is renowned for professional equipment, perhaps more significant are the millions of people using Canon gear to document their lives and precious moments. Birthdays, first steps, graduations, and everyday joys along life's meandering paths are all captured through cameras. Although Canon would love universal adoption of its cameras, the company understands that photography's power transcends brand loyalty.

Before any camera or lens development begins, the company's foundational love for photography serves as an essential ingredient in all products, from entry-level to professional. No Canon camera or lens exists without this grounding principle: work in service of photography.

The Canon T90's core design that Tokura helped develop has influenced nearly every Canon EOS camera for almost 40 years. The shutter release position, command dial arrangement, and overall curves and aesthetics of EOS cameras trace a clear lineage back to the 1980s. While cynics might view this consistency as stale, camera feel has become one of the most significant differentiators in today's market.

Canon insists it isn't tethered to the past and will never hesitate to change things, even if it disrupts the status quo. However, a delicate balance exists here. The refinements each model brings, though not universally improvements, are thoroughly considered. The prototyping process is extensive, with Canon creating handmade models and using advanced 3D printing to test each new product's feel.

Cameras must fit perfectly, with buttons and dials positioned optimally for target users. No detail is too small, as demonstrated by the Canon EOS R1's new grip design. When prototyping this feature, despite the possibility of digitally placing the pattern onto the mold, Canon's team deliberately chose traditional etching techniques. Each pattern placement undergoes visual inspection and manual adjustment to ensure precision.

Similarly, each ring pattern on Canon RF lenses receives careful consideration. Zoom, focus, aperture, and control rings all feature their own thoughtfully designed textures, allowing photographers to immediately identify which dial they're touching without looking. As Haruki Ota of the Canon Design Center explains, Canon employs a human-centric design philosophy where cameras and lenses must always be comfortable to hold and use.

Recent camera technology advancements focus heavily on making desired image capture easier, with autofocus technology playing a significant role. The evolution from film SLR days' archaic autofocus to today's lightning-quick systems represents a dramatic transformation. Modern cameras have progressed from sluggish, pulsing autofocus to systems that lock onto subjects so quickly they seem to read photographers' minds.

These improvements require constant, dedicated work and are hard-earned. One fascinating stop at Canon's Tokyo headquarters featured a long, hallway-like room in an auxiliary building where an extensive motorized track launches subjects toward cameras. Canon engineers maintain complete control over lighting and speed, enabling precise autofocus performance testing with carefully chosen parameters.

During demonstrations, technicians launched a lion photograph toward the camera at startling speed. The camera maintained perfect focus on the eye in the print, even when employees dimmed lights to simulate dawn and dusk conditions. Another demonstration showcased Action Priority autofocus in the Canon EOS R5 Mark II and EOS R1, currently supporting soccer, basketball, and volleyball to capture sharp shots of high-tempo, exciting moments.

Building these modes requires extensive field testing and real-world work from numerous photographers, including professionals Canon brings in to test new modes and products. Canon captured hundreds of thousands of photos of each sport to develop the Action Priority feature, representing countless kicks, dunks, spikes, and staggering amounts of time.

Koichi Fukuda, Canon's top engineer and Senior Principal Engineer of the IMG Development Unit, explained that Canon's celebrated Dual Pixel AF focuses on three key areas: intelligence, speed, and precision. This technology enables advancements in all three areas and represents one of Canon's most distinct technological advantages over competitors.

Image processing represents another area of significant focus. Kenji Takahashi from Canon's IMG Development Unit explained that image processing engineers work diligently to help photographers capture images they envision when pressing the shutter. Considerable behind-the-scenes work occurs inside cameras to make subtle, essentially imperceptible changes to color rendering and automatic white balance selection.

Recent deep learning developments help modern Canon cameras detect subjects and lighting conditions to improve automatic white balance. For scenes with blue skies, traditional white balance selection would cause faded, less saturated skies and disproportionately warm non-sky areas. Canon's AWB system can now ignore blue skies when selecting correct white balance for complex scenes.

Similarly, deep learning detects plant areas in photos, recognizing that green should remain truly green rather than appearing excessively tinted. The system can also select correct white balance while accounting for people in frames, which is especially important for portraits where overall scene balance might produce inaccurate skin tones.

Canon's reliability and camera testing facility provides fascinating, if briefly uncomfortable, insights into equipment durability testing. Yoshiyuki Kaizu demonstrated how Canon tests camera ruggedness, as professionals need equipment that works consistently regardless of conditions. Climate-controlled testing rooms include one heated to around 120°F with seemingly 100% humidity, followed by a subzero room that initially feels refreshing but quickly becomes excruciating.

In extreme environments far beyond typical photographer conditions, engineers test camera responsiveness, image sensor performance, and handling. While human visitors wouldn't want extended exposure to either room, cameras continue performing flawlessly. Common photographer scenarios like dropped equipment receive extensive attention through Canon's drop and impact testing machines.

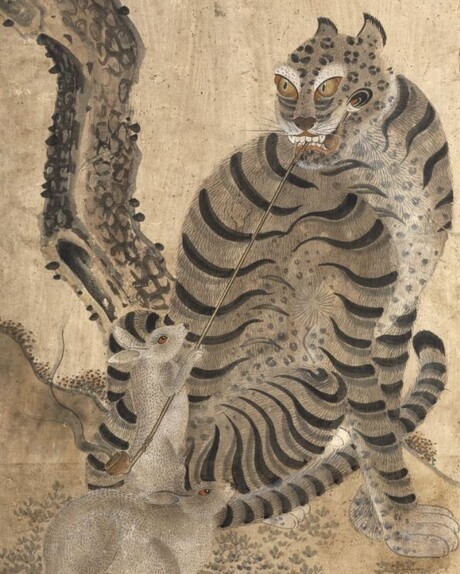

Canon's lens division reveals the critical importance of optical elements in image-making. While cameras capture vital light, lenses focus that light optimally before it reaches image sensors. Glass technology has advanced significantly in recent years, particularly regarding molding complex aspherical lenses. However, the most sophisticated elements are still hand-ground by Canon's most skilled artisans: Takumi.

These veteran craftsmen and craftswomen train for many years, and those reaching master or Meister level earn special uniform badges. The ultra-high precision components Takumi create by hand are vital for Canon's best lenses, including the impressive RF100-300mm F2.8 L IS USM telephoto zoom. In an industry where machines handle many processes, essential glass pieces still require the weathered hands of master artisans.

Canon maintains that human hands remain far more sensitive and precise than any machine for work requiring nanometer-level precision, making human touch irreplaceable. While optical designs may be computer-engineered by brilliant mathematical minds, many of Canon's finest lenses still rely heavily on analog human touch, and Canon believes this may always remain true.

Canon's BR optical elements represent perhaps the company's most impressive optical advancement, requiring a decade of development. These elements incorporate anomalous dispersion characteristics that change blue light refraction inside lenses. Though super-thin and barely perceptible, this ultra-thin element sandwiched between concave and convex elements changes how blue wavelengths focus on image sensors.

Compared to traditional elements, BR optics help blue light focus at the exact same location as red and green light, significantly reducing longitudinal chromatic aberrations. Canon adamantly maintains that no other company possesses technology as advanced as its BR lens system. The company takes similar pride in its SWC and ASC optics that reduce ghosting and flare.

Lens autofocus improvements cannot be entirely separated from better AF systems inside cameras, but faster and more powerful autofocus motors in lenses undoubtedly impact overall performance. Within Canon's RF lens lineup, five types of actuators drive autofocus, each with distinct advantages. The impressive Nano USM motor is tiny, quiet, and quick, used in many professional Canon zoom lenses.

Alongside technical tours and presentations, Canon extensively shared Japanese culture throughout the week, including local cuisine, a wonderful day in Kyoto, and even sumo wrestling. While Canon obviously wanted to show guests a good time, everyone's sincere desire to showcase Japanese culture, history, and customs was clearly genuine.

Canon's products and technologies are impossible to separate from their origins and remain deeply connected to their creators. While new cameras and lenses excite photographers, they come and go over the years. The people working on Canon photography equipment persist through all technological evolution and photo industry upheaval, representing what visitors will most remember and value from their Canon experiences.

Every photographer has experienced opening a new or new-to-them camera for the first time, a magical feeling because cameras are more than just cameras. They're how we capture life, enjoy free time, or for the especially fortunate and skilled, earn a living. However, photographers rarely consider the people who make their cameras possible – not just hundreds across dozens of teams who developed or manufactured specific models, but thousands more whose work echoes through decades.

Modern mirrorless cameras are sophisticated digital machines, but they remain ultimately made by people who, in many cases, love photography just as much as any enthusiast. Every shutter press represents years of hard work by talented, passionate individuals who pour their dedication into making photographic dreams a reality.