A groundbreaking experiment by YouTube creator Alec Steele has successfully demonstrated that functional QR codes can be forged directly into Damascus steel, pushing the boundaries of what's possible with traditional metalworking techniques. The project combines ancient forging methods with modern digital technology, creating what may be the world's first scannable QR code made entirely from forged steel.

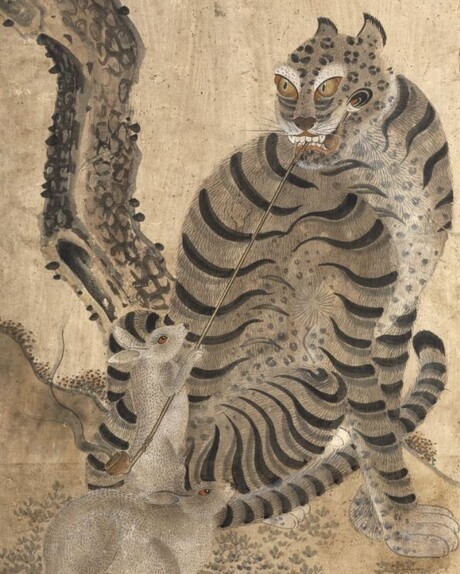

Damascus steel has gained tremendous popularity in the everyday carry (EDC) community over recent years, captivating enthusiasts with its distinctive marbled patterns created by combining multiple steel alloys. The characteristic visual appeal comes from forging different grades of steel together, then acid etching the surface to reveal contrasting colors between the alloys. While artisans have previously experimented with creating patterns and grids in Damascus steel, Steele's approach of creating a functional digital image represents an entirely new frontier.

QR codes, originally developed by a Toyota subsidiary for tracking automotive parts and vehicles on factory floors, have become ubiquitous in modern life. These square patterns are now used globally for everything from website access to mobile payments and inventory tracking, though their adoption by restaurants as digital menu replacements has drawn mixed reactions from consumers.

Steele initially planned to create a 27x27 grid QR code, which would have required precisely cutting and arranging 729 individual rectangular steel strips across two different alloys. This ambitious goal proved challenging due to the extreme precision required in cutting such thin, accurate metal channels. The process demanded extensive pre-planning and resulted in significant tool wear, with multiple cutting blades becoming unusable due to the demanding nature of the work.

The cutting process revealed additional complications as inconsistent cuts produced steel strips of varying thickness. While thicker strips could theoretically be ground down to proper dimensions, the material loss from cutting and grinding operations significantly reduced the total number of usable pieces. This forced Steele to modify his approach and scale down to a 21x21 grid pattern, requiring 441 strips instead of the original 729.

The smaller format came with trade-offs, as reduced QR code size means less information storage capacity. However, the modified approach proved more manageable given the material constraints and precision requirements of the forging process. Each strip had to be carefully positioned according to the digital QR code pattern, with different steel alloys representing the light and dark squares of the final code.

Once all strips were meticulously arranged according to the QR pattern, they were placed inside a specially designed die and welded shut in preparation for forging. The assembled package was then subjected to intense heat and pressure using a hydraulic press, which compressed the entire assembly into a solid billet. This stage represents the most critical and unpredictable part of the Damascus steel creation process.

Experienced blacksmiths know that numerous problems can occur during forging, ranging from pattern distortion due to uneven pressure distribution to complete failure if different steel alloys don't properly bond together. The intense forces involved can cause the carefully arranged pattern to warp beyond recognition, potentially making the QR code unreadable by scanning devices.

Fortunately, creating a decorative Damascus QR code doesn't require the structural integrity needed for functional items like knives or tools. Unlike blades that must withstand significant stress and wear during use, a steel QR code serves purely as an artistic piece. However, pattern warping remained a significant concern since excessive distortion could render the code unreadable to smartphone scanners.

The acid etching process revealed whether the ambitious experiment had succeeded. Steele tested the forged pattern with his smartphone's QR scanner and discovered that the code was indeed functional and readable. The etching successfully revealed the contrast between different steel alloys, creating the necessary visual distinction for QR code recognition.

To enhance the visual contrast further, Steele employed an additional technique by leaving the etched plate in coffee overnight. This coffee treatment intensified the staining effect, creating a much more pronounced contrast between the light and dark areas of the QR code pattern, making it easier for devices to scan and decode.

The successful experiment yielded multiple plates from the original billet, which Steele made available for purchase through his website. The project's success opens new possibilities for integrating modern digital elements into traditional metalworking, potentially inspiring other craftspeople to explore similar combinations of old and new technologies.

This breakthrough raises intriguing questions about future applications in knife making and handle design. The possibility of incorporating functional QR codes into knife handles or blade surfaces could revolutionize how craftspeople sign their work or provide information about their creations. Such integration could allow customers to access detailed information about the blade's creation process, materials used, or even the artisan's contact information simply by scanning their smartphone over the finished piece.