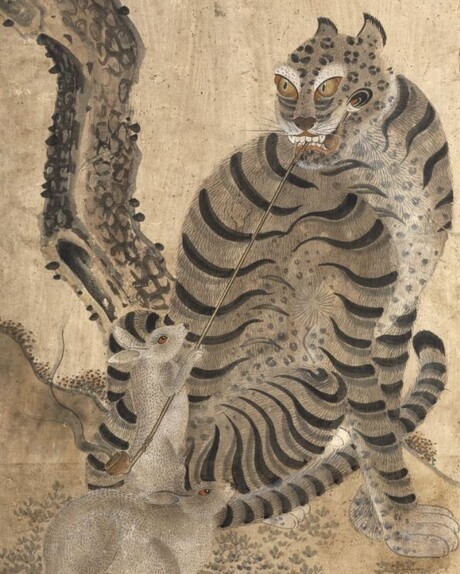

India faces a striking contradiction in its construction industry: while bamboo scaffolding supports the nation's towering glass buildings and concrete structures, bamboo itself remains largely absent from permanent architecture. This paradox highlights the complex relationship between traditional knowledge and modern construction practices across the subcontinent.

Across Indian cities, workers routinely construct multi-story bamboo frameworks using only poles, rope, and skills passed down through generations. These temporary structures must withstand monsoon winds, seismic activity, and the dynamic loads of construction while remaining economical enough to be erected and dismantled repeatedly. The scaffolding industry handles billions of dollars in construction projects annually, yet this expertise struggles to translate into permanent bamboo architecture.

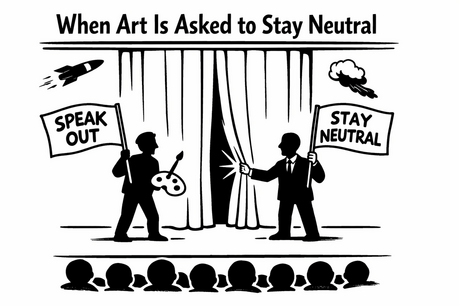

The knowledge exists outside formal engineering education, transmitted through apprenticeship systems that give workers an intuitive understanding of material behavior. Years of regional expertise dictate which bamboo varieties serve specific structural purposes, reveal the influence of weather on joint performance, and establish the methodical timing needed to assemble poles into robust frameworks. However, when institutional constraints are removed, bamboo expertise can flourish dramatically.

At the 2023 Surajkund Craft Fair, ninety skilled bamboo artisans from Northeast India constructed a complex exhibition pavilion in just sixty days. The temporary structure featured woven bamboo lattice and hyperbolic roof profiles that matched the precision found in permanent construction. Artisans adapted their building approach and joinery methods as conditions demanded, demonstrating the dynamic and experience-driven learning that drives bamboo architecture.

Despite institutional resistance, several Indian architects and organizations have successfully demonstrated bamboo's viability for permanent construction across multiple scales and contexts. Bamboo House India has constructed over 750 prefabricated bamboo homes across the country, with units ranging from basic 200,000 to 500,000 rupee starter houses to upmarket 2 million rupee models, proving bamboo can serve diverse economic segments.

The company's success stems from systematic approaches to barriers that typically block bamboo construction. They have navigated regulatory reforms through National Bamboo Mission advocacy, incorporated fire-retardant treatments to meet safety codes, and documented performance data to convince reluctant banks and insurance companies. Their units cost up to 40 percent less than conventional construction and can be built in weeks rather than months, supporting over 10,000 livelihoods annually while diverting plastic and agricultural waste from landfills.

In Assam, post-2018 flood reconstruction revealed bamboo's potential under different constraints. SEEDS India and architect Kamal Chawla constructed over eighty disaster-resilient bamboo stilt houses using humanitarian relief frameworks that bypassed normal regulatory barriers. The project merged traditional stilt-house wisdom with modern engineering, resulting in hybrid structures featuring bamboo columns set in concrete foundations and rubberized joints designed for earthquake resilience.

The houses have withstood multiple monsoons while providing sanitation upgrades and cultural familiarity for residents. The project succeeded through participatory construction methods that preserved local building traditions while meeting contemporary performance standards. However, the 20 percent cost premium over vernacular construction and the special regulatory context required for approval highlight the challenges of scaling such approaches beyond disaster relief scenarios.

Building codes written for concrete and steel contain no provisions for bamboo's unique properties. The material's natural variability, where each culm differs in diameter, length, and taper, confounds regulatory systems designed for industrial standardization. Bamboo House India has influenced policy through advocacy work, helping move bamboo out of restrictive "tree" classifications that once required forest department permits for urban construction.

Cultural barriers prove equally challenging, as deep-rooted beliefs equate concrete with advancement and bamboo with deprivation. This makes cultural attitudes powerful obstacles to change, especially in rural India. Banks remain reluctant to finance bamboo construction despite documented cost savings and enhanced durability from pioneering projects. Insurance companies struggle to assess risks for non-standard materials, creating economic barriers that reinforce cultural prejudices.

Architecture schools teach standardized materials while ignoring bamboo's complex requirements for iterative design and real-time problem-solving. Neelam Manjunath, India's "Bamboo Ambassador" and founder of Manasaram Architects, has spent more than thirty years uniting ancestral bamboo knowledge with modern construction innovations. Her practice routinely requires extensive documentation to convince authorities, constant advocacy to overcome banking obstacles, and as much time training contractors as designing buildings.

The supply chain dynamics differ fundamentally between scaffolding and building applications. Scaffolding needs uniform poles for versatility, but permanent builds require a broader array of bamboo products, each with specific harvesting, processing, and quality standards. While scaffolding represents a thriving industry worth billions annually, permanent bamboo construction remains confined to experimental projects and niche applications.

Rural artisans possess sophisticated bamboo processing knowledge but lack access to urban construction markets. Urban construction companies understand project management and regulatory compliance but lack bamboo expertise. The knowledge exists in isolated silos, preventing the integration necessary for mainstream adoption.

Successful projects demonstrate pathways beyond the current impasse, revealing the systematic changes required for broader adoption. Bamboo House India's prefabrication model shows how manufacturing approaches can standardize bamboo products while preserving cost advantages. The Surajkund pavilion proves that when regulatory constraints disappear, sophisticated bamboo architecture can emerge rapidly.

Building code reforms could accommodate natural material variability rather than demanding industrial standardization. The regulatory flexibility available for temporary structures or post-disaster reconstruction could inform permanent building standards. Educational initiatives might connect architecture students with both scaffolding workers and traditional bamboo practitioners, creating cross-pollination between knowledge systems that currently operate in isolation.

The bamboo paradox ultimately reflects broader tensions within India's development trajectory between traditional knowledge and technical modernization, local materials and global supply chains. Case studies reveal that the expertise already exists in different parts of the country, with scaffolding workers understanding structural behavior, traditional artisans possessing processing techniques, and contemporary architects having developed regulatory strategies.

Whether India can harness its extraordinary bamboo expertise for permanent construction will ultimately determine if the nation can move beyond the paradox of trusting bamboo to support its future while refusing to build that future from bamboo itself. The contradiction continues as bamboo surrounds Indians daily in scaffolding that enables the country's construction boom, while proven permanent bamboo buildings remain exceptional rather than routine.